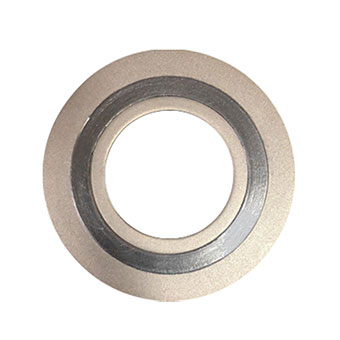

Product Name: Spiral Wound Gasket

Class Name: Sealing Product

Date: 2022-07-13 Reading times: 350

Description

Spiral wound gasket is alternately wound by v-shaped or W-shaped metal strip and nonmetallic strip filler, in which the metal strip ensures the resilience of the gasket. Nonmetallic strip packing ensures gasket tightness. Due to the combination of the above materials, the metal winding pad is usually used in the temperature and pressure fluctuations of the working conditions, according to the requirements of the use of the winding part of the inner diameter can be with internal and external metal ring

Spiral wound gasket can be divided into A basic type spiral wound gasket, B inner ring spiral wound gaskets, C outer ring spiral wound gaskets, and D inner and outer ring spiral wound gaskets.

A basic tenon groove surface

A basic spiral wound gasket is made of metal winding tape and shaped packing, without inner and outer ring, suitable for tenon flanges.

B inner ring concave and convex surface

B inner ring spiral wound gasket is the same as the A basic type except that the outer ring has a centering strengthening ring, suitable for concave and convex flanges.

C outer ring convex surface

C outer ring spiral wound gaskets is the same as the basic type, with inner strengthening ring, suitable for concave and convex flanges. An inner stiffener ring is installed to protect the gasket wound area from erosion or bending by the medium.

D inner and outer ring spiral wound gaskets

D inner and outer ring spiral wound gaskets the structure is the same as B type inner ring spiral wound gasket, except with inner strengthening ring, suitable for convex flange or plane flange

Advantage

1, Good sealing: the section structure is simple, and has a self-sealing effect, reliable sealing performance.

2, High wear resistance, high temperature resistance, oil resistance, alkali resistance, grinding, chemical erosion and other environment still play a good sealing, damping effect.

3, With very good wear resistance, high tensile strength, good elasticity.

Application

1, Used in petroleum, chemical, metallurgy, electric power, shipbuilding, machinery and other industries of pipeline.

2. Used for static sealing at flange joints of valves, pressure vessels, condensers, heat exchangers, etc.

3, Because of high mechanical strength, easy to use, good compression resilience, more suitable for severe temperature change occasions.

4, Easy installation, low gasket pre - tightening pressure.