Product Name: Binding Material

Class Name: Modified PTFE

Date: 2022-07-15 Reading times: 397

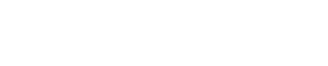

Classification and specification: normal temperature adhesive (1KG/ set), high temperature adhesive (1KG/ bottle)

Surface natrifying steps:

1, the first has been turned ptfe products, including ptfe plate or poly four

Fluoroethylene film with acetone or alcohol cleaning, remove surface oil and dirt

2, at room temperature, the clean and dry ptfe products have been immersed in the preparation of sodium naphthalene

Soak in the solution for 1 to 10 minutes and remove;

3. After removal, clean with normal temperature water to remove NAH and N AOH and other residues, and wait for PTFE

The surface of the ene is dark brown, both for treatment, dry or oven drying;

4. The processed products should be stored away from light and used within three months.

Bonding step

1, high temperature binder (1KG/ bottle) :

Apply the binder to the sodified tetrafluoron board, and wait until the binder is completely cured High temperature blowing (the temperature of the normal hot hair dryer is ok, the surface can be used after opening a little

Do not need to melt completely), bonded on both sides, and then flat stainless steel material to 2 The surface is flattened and clamped with appropriate external force until it solidifies (about 24 hours).

2, normal temperature adhesive (1KG/ set) :

Mix two bottles in proportion (normal 2:1), stir them evenly, and evenly apply them on the surface of the adhesive.The total thickness of the glue layer is about 0.15mm on both sides. The two sides are bonded, and then Flat stainless steel materials to 2 surfaces of appropriate external pressure and clamping, to be cured Yes (24 hours or so).